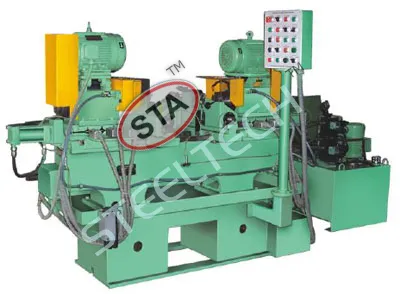

We are Manufacturer, Supplier, Exporter of Fully Automatic Centering & Plunge Facing Machines and our setup is situated in Kolhapur, Maharashtra, India.

Features :

- Toughened Guide ways of Machine Bed

- Slide Feed Head Stocks

- High Productivity

Specifications :

| Admitted work length • with Single vice min • with Double vice min • with Double vice max. |

40 mm 110 mm 500 mm |

| Min. job dia. clamped in vice | 15 mm |

| Max. job dia. clamped in vice | 125 mm |

| Job Clamping system | Self Centering vice by Hydraulic motor force 2000 kg. |

| Rapid Travel Speed | 4200 mm/min |

| Spindle speeds | 750, 1000 RPM |

| Max. Stroke of Slide | 50 mm |

| Slide Feeding | Infinitely variable with hydraulic. |

| Max. Plunge face Diameter | 63 mm |

| Centre Drill Sizes | BSS3 TO BSS6/as per ISI |

| Total Machine Power • Spindle Power • Hydraulic Motor Power |

10.15 H.P 3 H.P/each 3 H.P |

| Coolant Motor | 0.15 H.P/40 lpm |

| Overall Size LxWxH | 2000 / 1300 / 1600 |

| Machine Weight | 1250 Kgs. |

Head Stock :

Two Spindles are supporated by two taper roller bearigs at both sides. Both head stock are slide feed by Hydraulic. One head stock permanently fixed & other is adujustable to accommodate different job length. Drive is by timing belt. Change of speeds is changing timing pulley.

Tool Holders :

Facing tools are indexable insert type. Centre drill holders is used to hold and adjust centre drill. Depending on application, Chamfering, O.D. Turning, tools can be supplied.

Vices :

The job is clamped by to self centering vice assy.

(LH/RH scres with G.M.T nut / V-flat Jaws.) The vice screw are rotated by hydraulic motor.

Machine Bed and Rack Pinion system :

The box and cross ribbed bed with toughened guide ways ensures rigidity of machine bed. Rack and pinion systems is given to adjust vice assy, adjustable headstock to required length.

- Circular Saw Machines (Saw Cutters / Cutting Saws / Sawing Machines)

- Fully Automatic Band Saw Machines

- Semi Automatic Band Saw Machines

- Double Column DCA - 200, 260, 340

- Double Column DCM - 340,450, 550, 650

- Vertical Bandsaw Machines

- Miter Cutting Bandsaw 0 - 45

- Milling Type Facing & Centering Machines

- Fully Automatic Centering & Plunge Facing Machine Model - CFAM

- Boring Machines

- Milling Machines

- Rotary Transfer Machines

- Broaching Machines